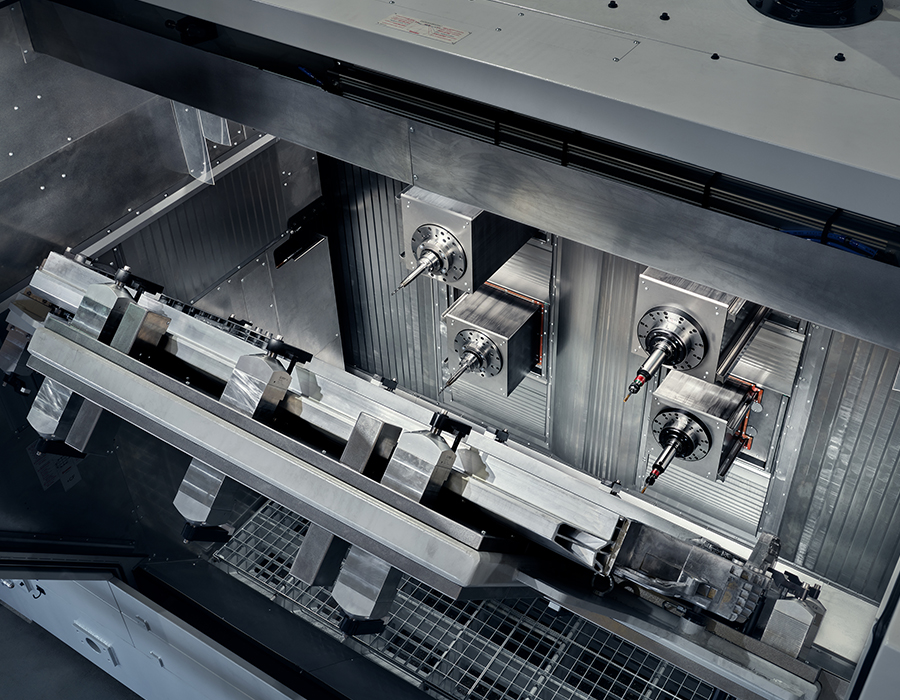

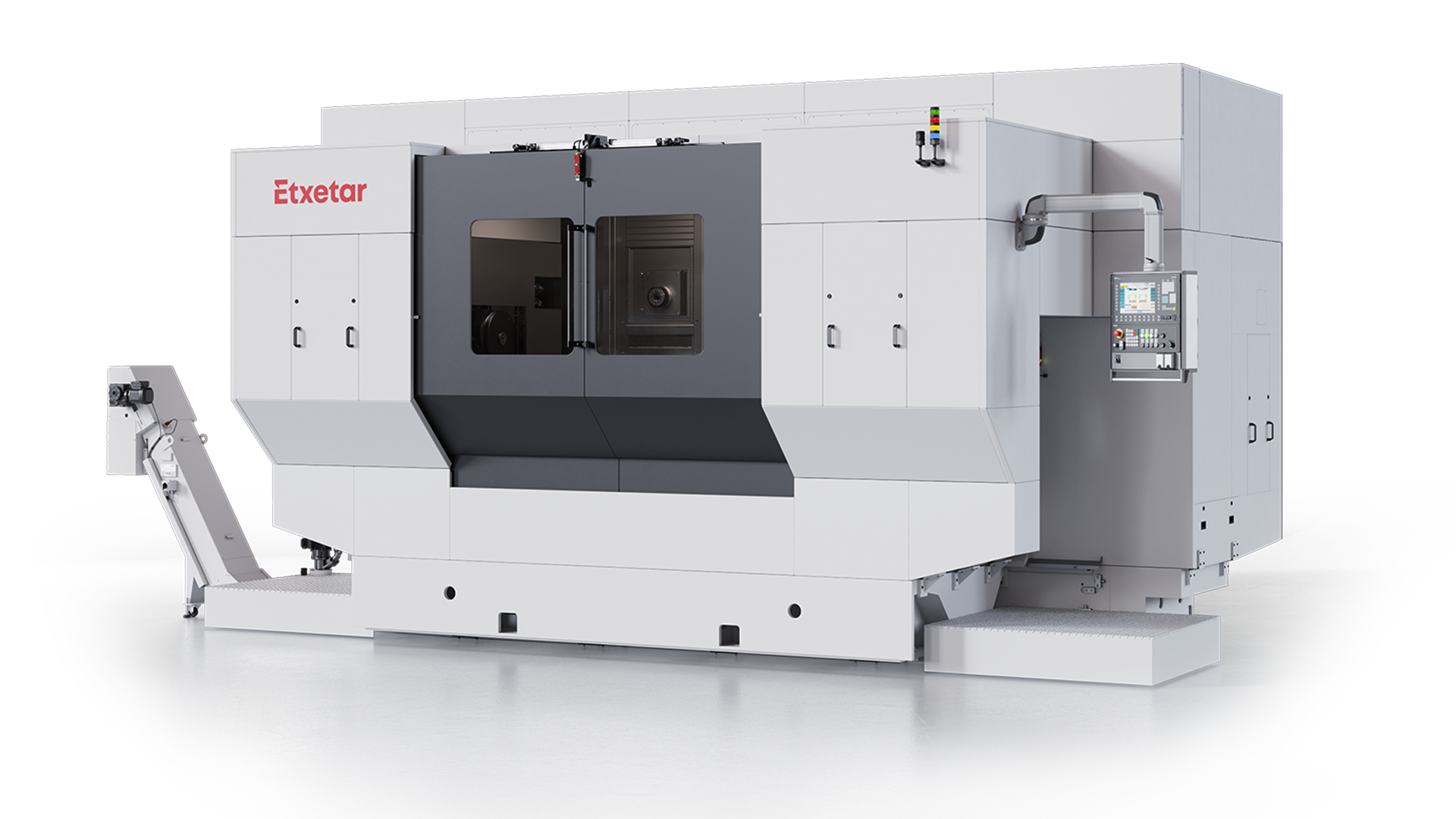

Xflex Twin +

Our flexible machining center solution for structural parts capable of machining up to 2.5 m x 1.8 m workpieces.

Introduction

As part of the Xflex platform, the Xflex Twin + is a solution with up to 2 adjacent units and 4 spindles in total. The Twin + will increase the throughput while minimizing floor space usage. The Twin + also provides more flexibility as each 3axis unit is completely independent.

The Xflex Twin + is the most optimum solution for high productivity scenarios of structural parts.

- High adaptability to different production scenarios, by means of a modular platform that allows multiple spindles per machining unit, and up to two adjacent machining units, for a total of 4 spindles. Independent Y axis per machining unit and independent spindle Z axis available for the dual spindle configuration.

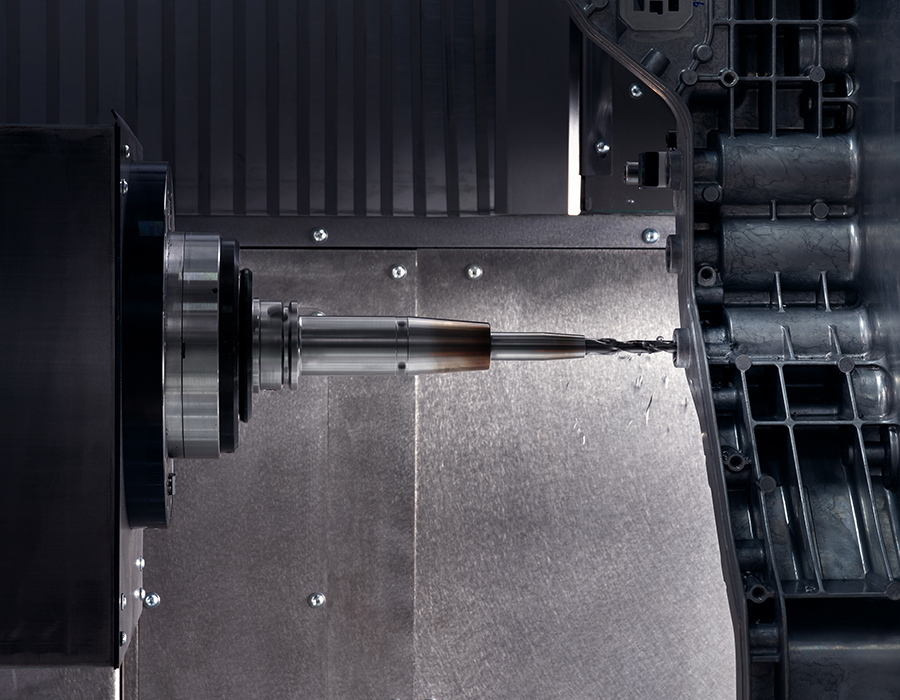

- Compatible with Dry, MQL or high-pressure coolant machining.

- Design focused on favoring chip shedding.

- Ergonomic design for tool change and maintenance activities.

- Suitable configuration for gantry, robot, or manual load.

- 4 axis machining centers. All linear axes provided with linear scales.

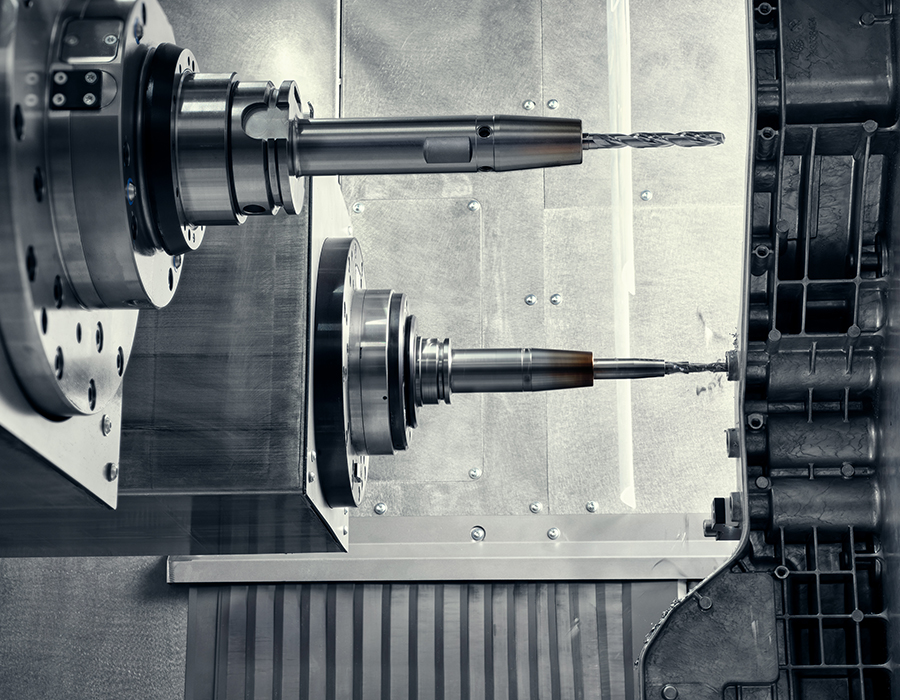

- Tool interface HSK-63, HSK-80, or HSK-100. Other interfaces upon request.

- Motorized or conventional spindle.

- Chain type automatic tool changer with 24 or 36 tools. Tool capacity can be upgraded upon request.

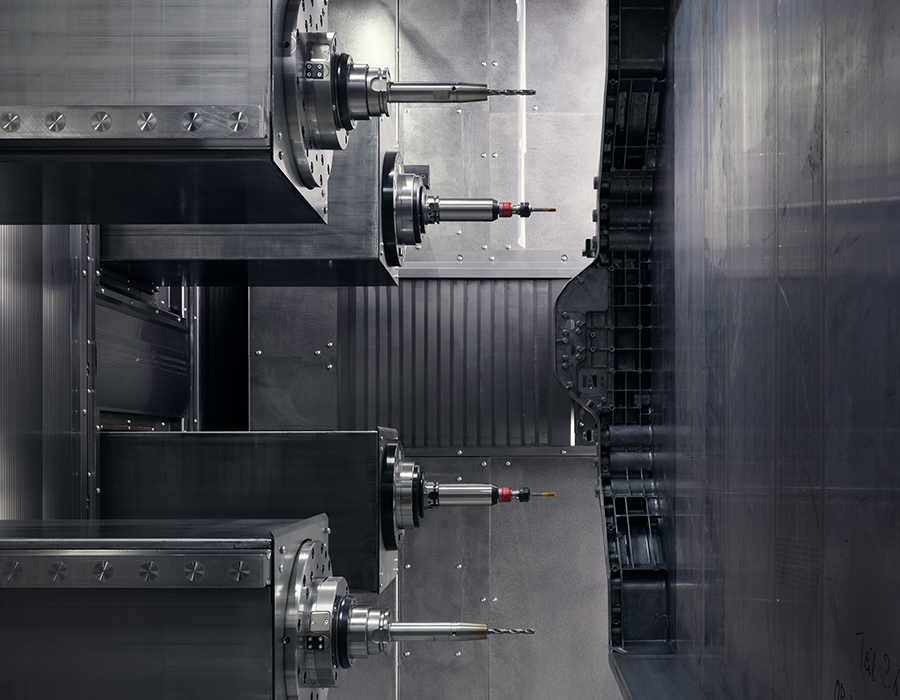

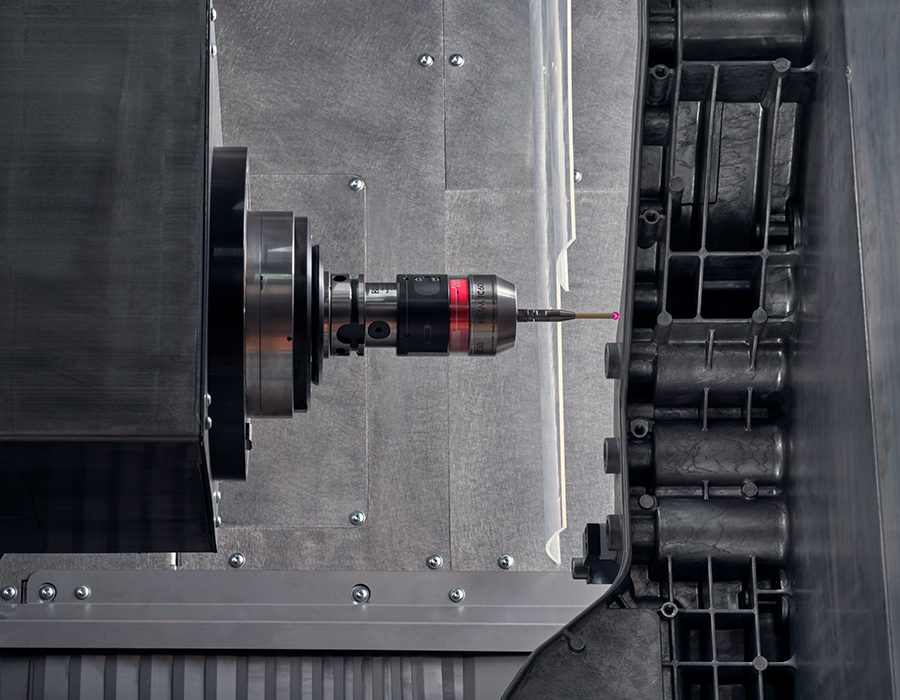

- Multiple tool breakage detection systems (laser, mechanical check, tool monitoring, etc.).

- Tool presence control in the tool exchange position between spindle and magazine.

- Unobstructed chip shedding designed for MQL machining.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so chips fall directly to the conveyor.

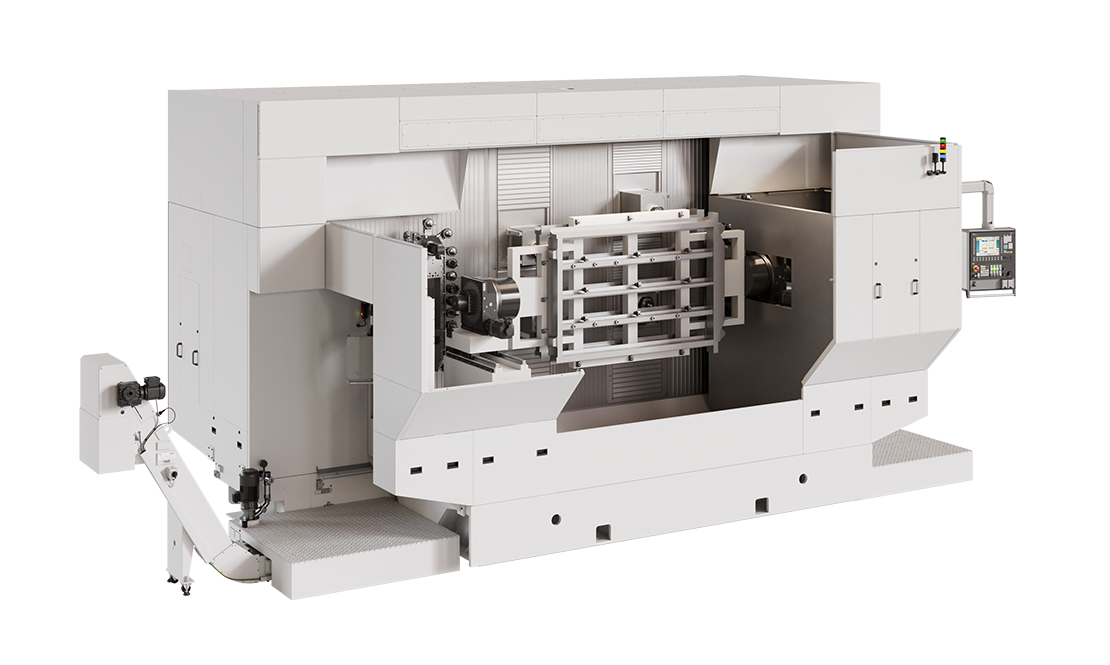

Machine architecture

Machining unit

- 3 axis unit (X/Y/Z), (X/Y1/Y2/Z1/Z2) in case of 2 spindles unit.

- 1 or 2 spindles per machining unit.

- 1 or 2 units, depending on the production volumes.

Fixture options

- 1 or 2 fixtures (on each side). Limited by the part

- Axis: A / W.

Load/unload options

- Gantry load, by means of a loader integrated in the machine design.

- Robot load.

- Manual load. Directly to the fixture.

1

2

3

-

1 Machining unit

- 3 axis unit (X/Y/Z), (X/Y1/Y2/Z1/Z2) in case of 2 spindles unit.

- 1 or 2 spindles per machining unit.

- 1 or 2 units, depending on the production volumes.

-

2 Fixture options

- 1 or 2 fixtures (on each side). Limited by the part

- Axis: A / W.

- 1 or 2 fixtures (on each side). Limited by the part

-

3 Load/unload options

- Gantry load, by means of a loader integrated in the machine design.

- Robot load.

- Manual load. Directly to the fixture.

We can help you with the manufacturing process of many other applications