Introduction

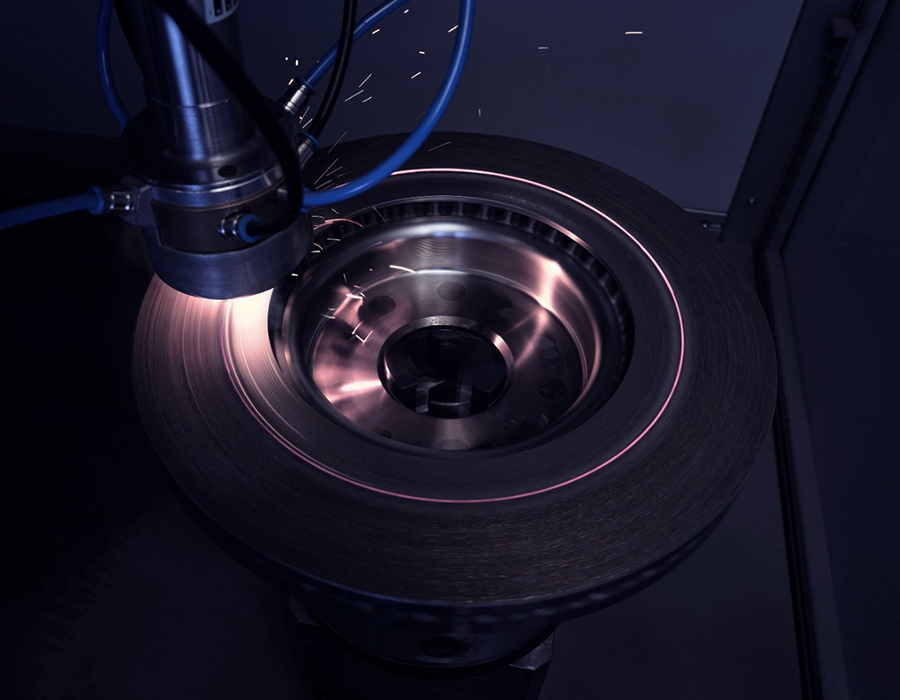

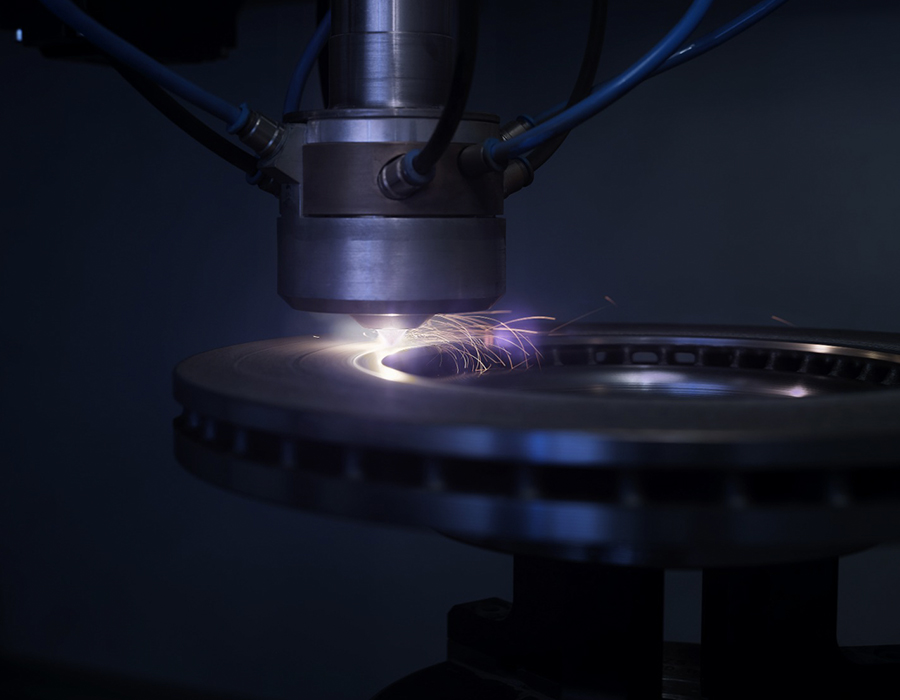

As an innovative response to the European EURO 7 regulation, the BD Concept is our state-of-the-art brake disc cladding solution. It aims at minimizing environmental impact due to brake disc fine dust emissions, paving the way for greener and more sustainable automoviles. With a special focus on productivity and efficiency, this machine concept is tailor-made for brake disc processing, showcasing both specialized design and advanced functionality.

- Incorporates a new operation to the brake disc production process, highlighting our commitment with new technologies.

- Offers high-production capabilities with expertise.

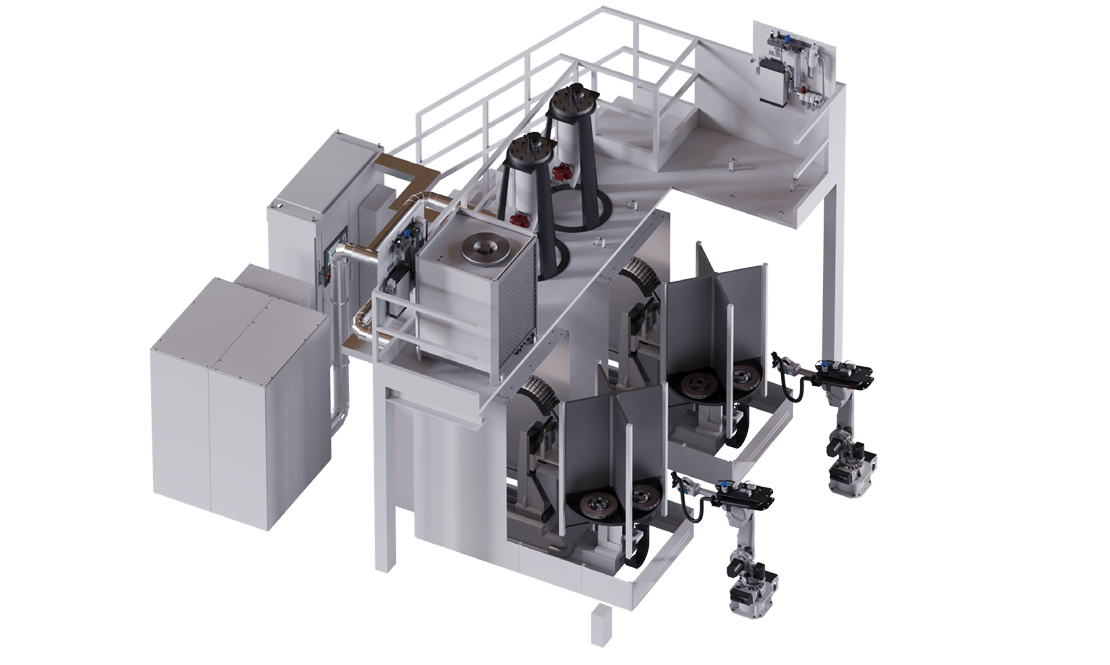

- Features a patented automatic powder coating filling system.

- Benefits from our solid 10-year accumulated experience in powder coating processes.

- Enhanced real-time monitoring systems for cladding operations, ensuring quality and reliability.

- Prioritizes exceptional productivity with up to 90% laser ON time.

- Equipped with an automatic powder feeder suitable for non-stop production.

- Intermediate cleaning station between processing.

- Independent units for processing different powder types.

- Laser Cladding Head: Efficient, modular, versatile and suitable focused on high volume production.

- Advanced In-Situ Monitoring for Cladding Operations, including multisensor measurements controls.

- Powder flow rate: up to 200 g/min.

- Power of laser: Up to 22 kW.

- Laser beam diameter: 1.5-3.5 mm.

Machine architecture

We can help you with the manufacturing process of many other applications