Introduction

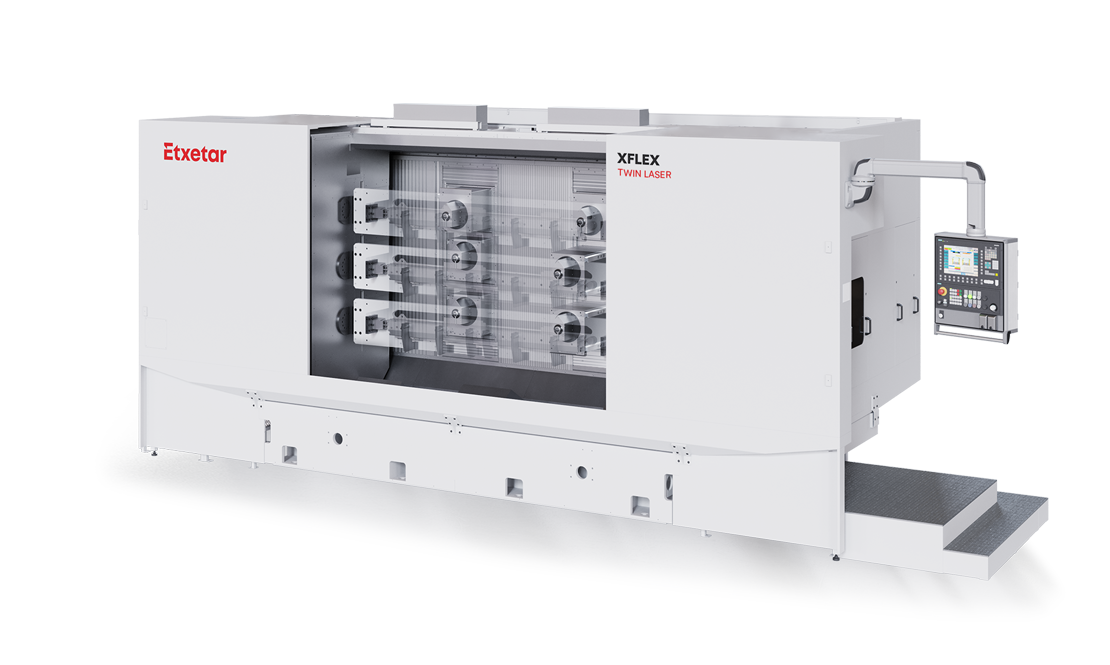

As part of the Xflex platform, the Xflex Twin Laser is a unique solution for laser cutting multiple parts, with up to 2 adjacent units and a total of 6 laser heads, which significantly reduces the cycle time compared to a traditional machining approach, and multiplies the throughput with better floor space usage.

- Up to 50% faster cycle times than traditional machining.

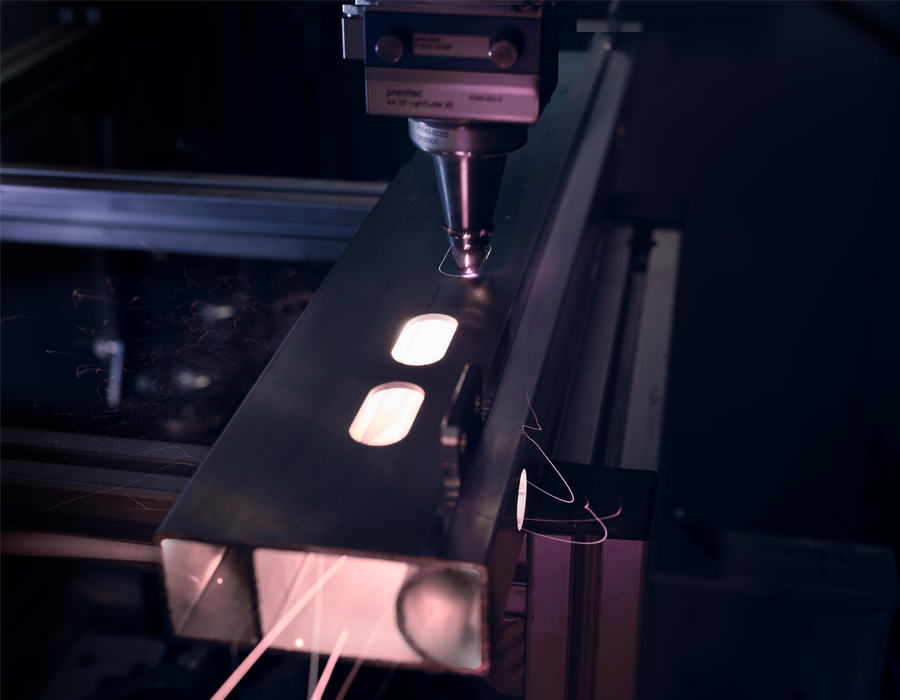

- No coolant or cutting tools needed.

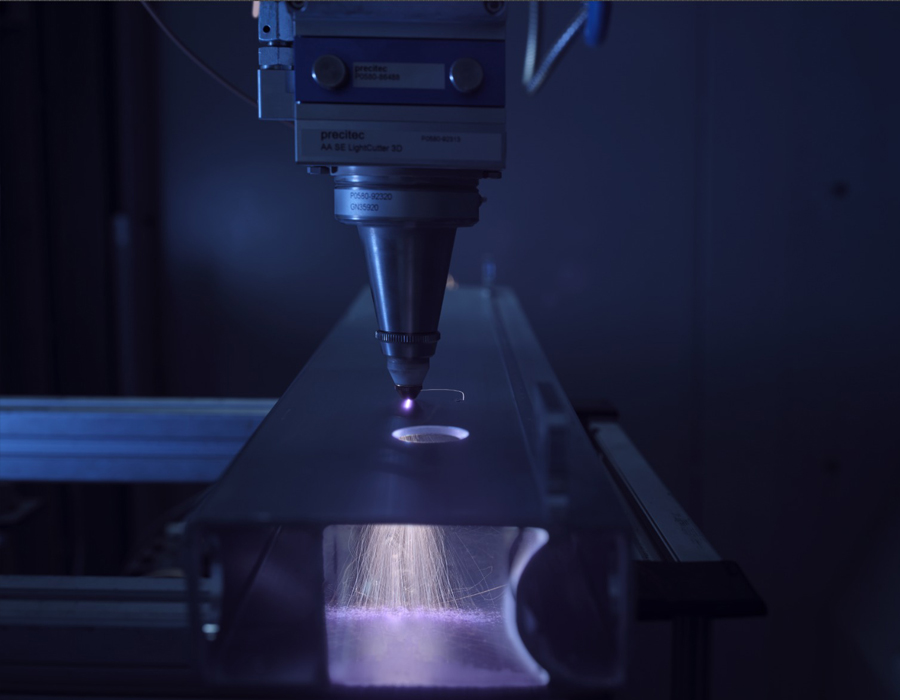

- Homogeneous CNC quality with minimum burrs.

- Highest recycling value for aluminium or steel slugs.

- High adaptability to different production scenarios, by means of a modular platform that allows multiple heads per 3axis unit, and up to two adjacent units.

- Design focused on favoring chip shedding.

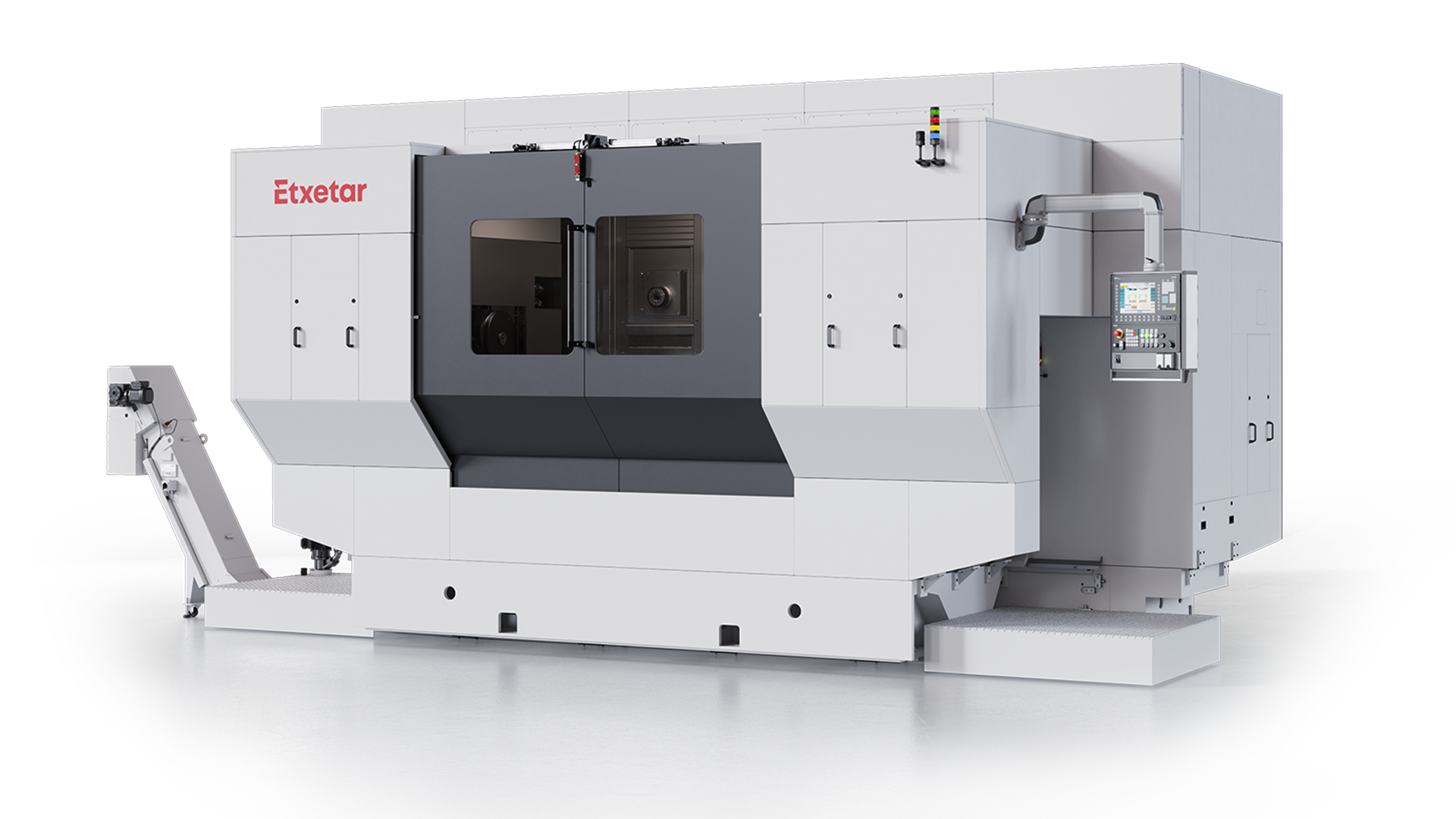

- Ergonomic design for maintenance activities.

- Increased machine availability.

- Suitable configuration for gantry, robot, or manual load.

- 4 or 5 axis laser cutting center. All linear axes provided with linear scales.

- Independent head Z axis.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so slugs fall directly to the conveyor.

- 0 cutting forces on part/fixture.

Machine architecture

Machining unit

- 3 axis unit (X/Y/Z), up to 5 axis unit (X/Y/Z1/Z2/Z3) in case of 3 heads unit.

- Each laser head can include an additional axis (C).

- 1, 2 or 3 laser heads. Limited by the part swing diameter and process tolerances.

- 1 or 2 units, depending on the production volumes.

Fixture options

- 1, 2 or 3 fixtures. Limited by the part swing diameter and process tolerances.

- Axis: A.

- Possibility of tombstone fixture for overlapping load and unload of parts.

Load/unload options

- Gantry load, by means of robot on rail.

- Robot load, by means on floor mounted robot.

- Manual load. Directly to the fixture.

1

2

3

-

1 Machining unit

- 3 axis unit (X/Y/Z), up to 5 axis unit (X/Y/Z1/Z2/Z3) in case of 3 heads unit.

- Each laser head can include an additional axis (C).

- 1, 2 or 3 laser heads. Limited by the part swing diameter and process tolerances.

- 1 or 2 units, depending on the production volumes.

-

2 Fixture options

- 1, 2 or 3 fixtures. Limited by the part swing diameter and process tolerances.

- Axis: A.

- Possibility of tombstone fixture for overlapping load and unload of parts.

-

3 Load/unload options

- Gantry load, by means of robot on rail.

- Robot load, by means on floor mounted robot.

- Manual load. Directly to the fixture.

We can help you with the manufacturing process of many other applications