Biela Concept

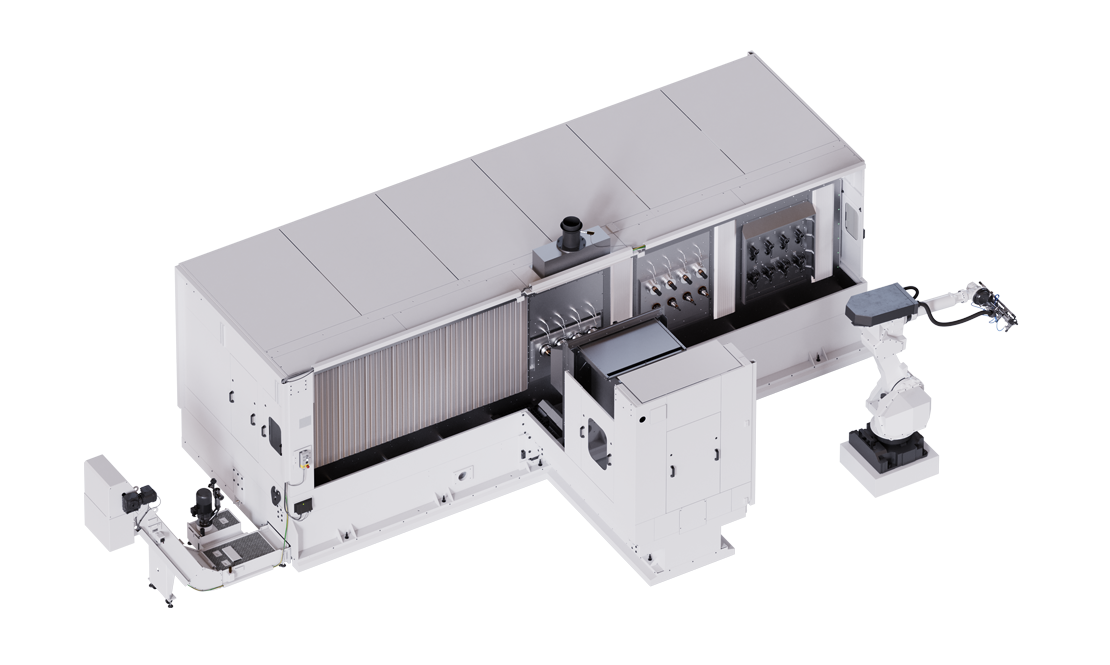

Our multi-spindle SPM modular design.

Introduction

Based on a common platform of components, the Biela Concept offers a robust and modular design that is arranged to address the full spectrum of connecting rod machining operations.

Finally, you do not have to sacrifice productivity to achieve more flexibility. Based on a single standard platform, the Biela Concept provides a robust modular design with a combination of features that help you increase your competitiveness.

- Rigid construction – robust architecture to provide high machining accuracy.

- 4, 5 or 6 connecting rods per fixture.

- X axis displacement of the multi-spindle heads leads to higher precision.

- Unobstructed chip shedding, designed for MQL or wet machining.

- Ergonomic tool change.

- Free access for maintenance.+K12.

- All linear axes provided with linear scales.

- Diverse tool interfaces depending on the operation.

- Unobstructed chip shedding designed for MQL machining.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so chips fall directly to the conveyor.

Machine architecture

Machining unit

- Clamping fixture mounted to column with Y, Z axes. The clamping fixture produces the Z motion for a higher precision.

- 1 or 2 multi-spindle units with independent X axis. Each multi-spindle unit is equipped with different rows of spindles.

- Multi-spindle heads with 4, 5 or 6 exits/row and up to 4 rows/head.

- 1 or 2 multi-spindle units, depending on the production volumes.

Fixture options

- 4, 5 or 6 parts per fixture.

- NC motion in the fixture for automatic change-over between parts as an option.

Load/unload options

- Gantry load.

- Robot load.

- Manual load. Directly to the fixture or by means of a loader integrated in the machine design.

1

2

3

-

1 Machining unit

- Clamping fixture mounted to column with Y, Z axes. The clamping fixture produces the Z motion for a higher precision.

- 1 or 2 multi-spindle units with independent X axis. Each multi-spindle unit is equipped with different rows of spindles.

- Multi-spindle heads with 4, 5 or 6 exits/row and up to 4 rows/head.

- 1 or 2 multi-spindle units, depending on the production volumes.

-

2 Fixture options

- 4, 5 or 6 parts per fixture.

- NC motion in the fixture for automatic change-over between parts as an option.

-

3 Load/unload options

- Gantry load.

- Robot load.

- Manual load. Directly to the fixture or by means of a loader integrated in the machine design.

We can help you with the manufacturing process of many other applications