iR - oR - tR

Introduction

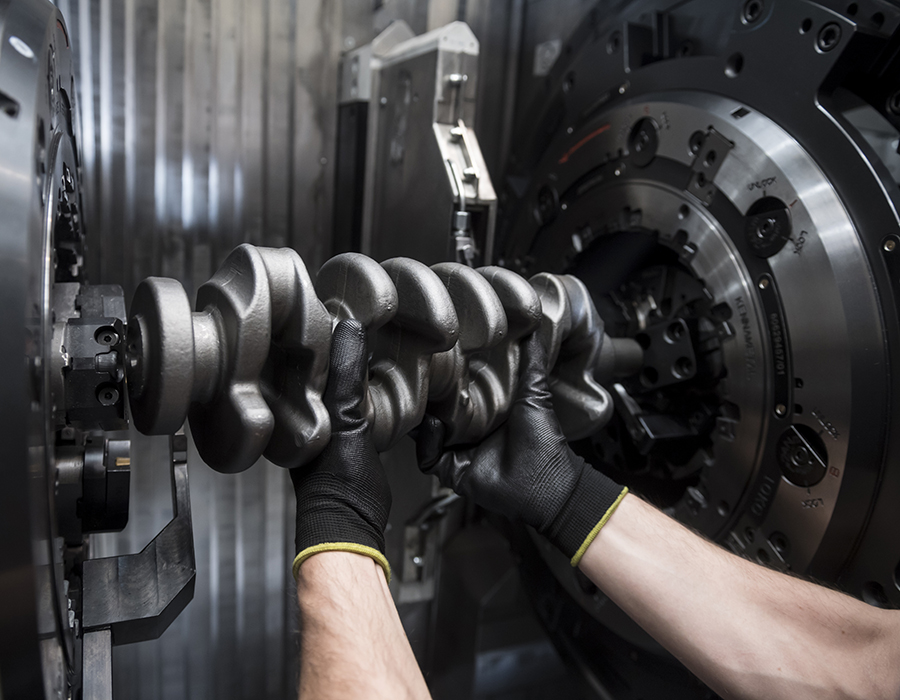

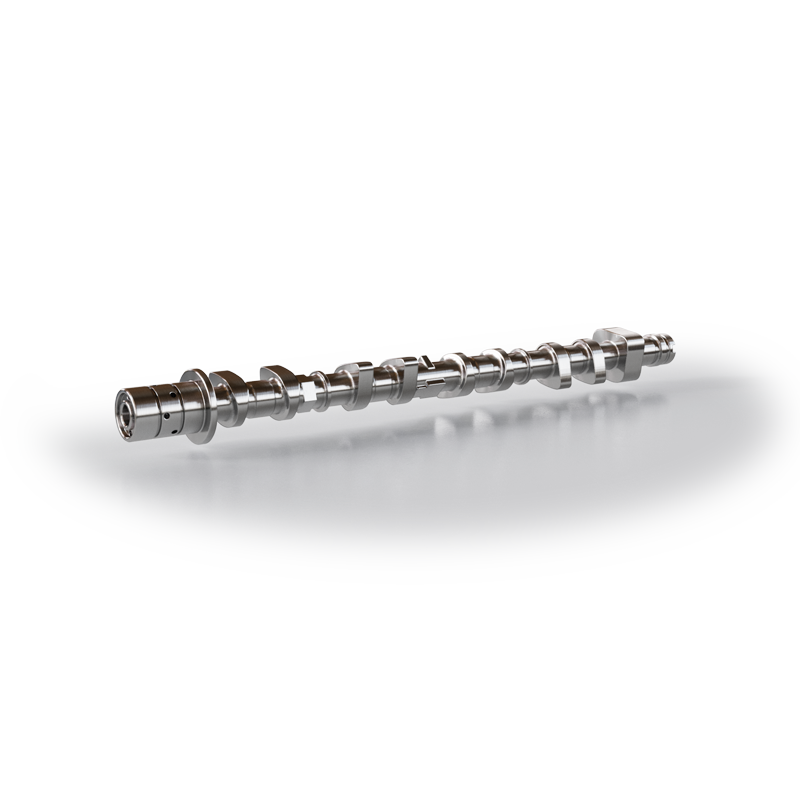

The iR series of machines have been developed applying extensive know-how of high productivity systems for steel and cast iron crankshafts and camshafts.

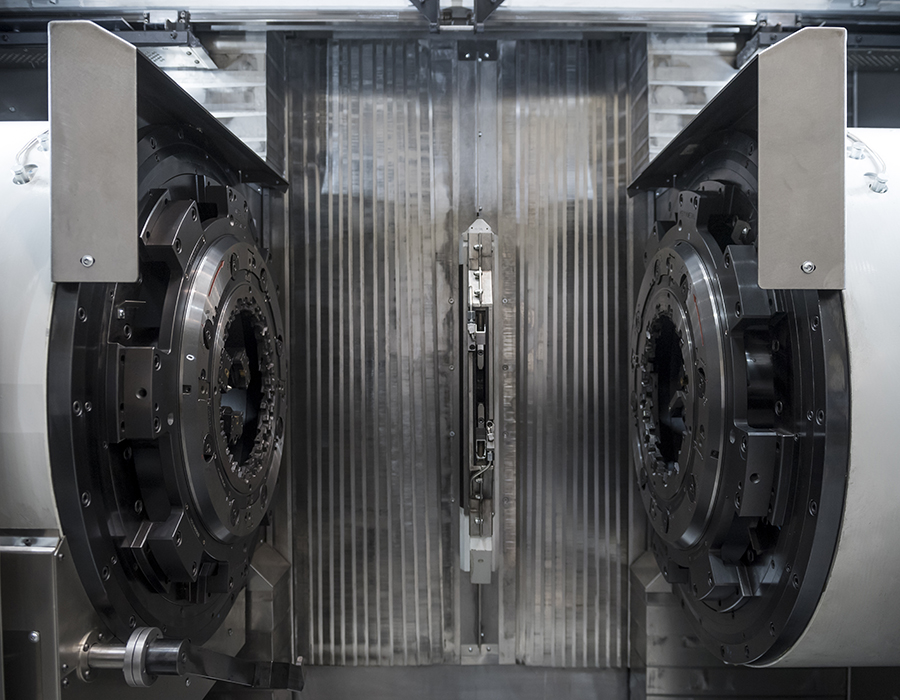

Based on a milling center configuration and our experience with the XFlex series, it is equipped with 2 sliding NC controlled workpiece driving spindles, a NC independent steady rest and 2 internal milling tool spindles, offering extra capabilities and flexibility.

Thanks to its modularity, it is prepared to be retooled into an external milling machine or a turn / turn-broach machine.

Our unique configuration allows for an increased machine stiffness, improved chip shedding, and a safe and easy access for maintenance.

- High level of modularity between ID, OD and TTB.

- 2 sliding NC controlled workpiece drive spindles. Electronic spring to control force between centers.

- Standard out off the shelf pull-down and compensating clamping chucks, with fixed centers. Fully sealed and low maintenance.

- Highest stiffness of workpiece spindles, due to reduced overhang length from chuck face to guiding.

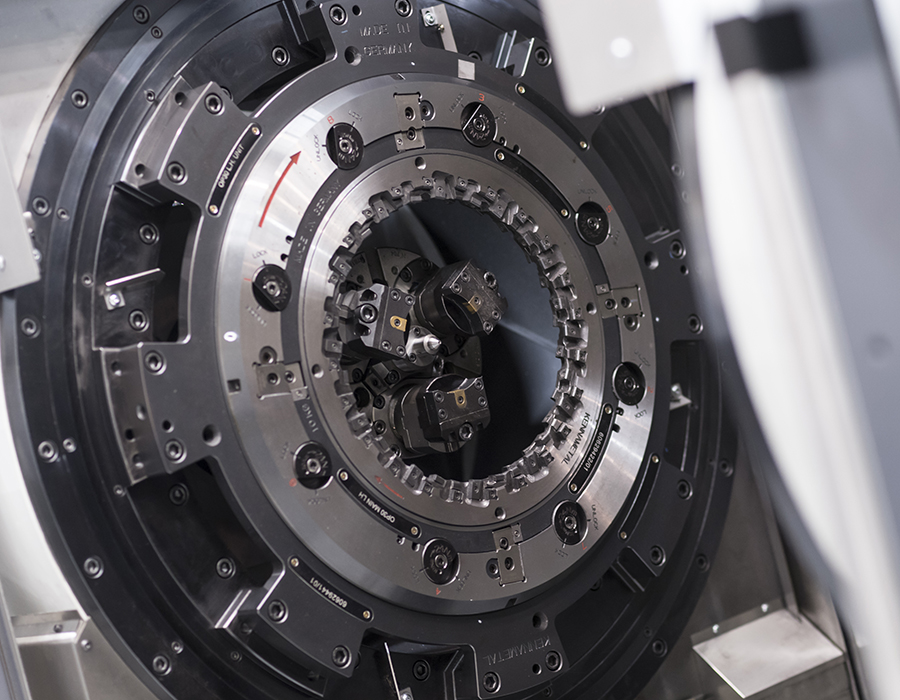

- Highest stiffness of tool spindles, due to bigger bearings.

- Low maintenance components, as the Direct Drive motors for workpiece spindles.

- Design focused on favoring chip shedding.

- Ergonomic design for tool change and maintenance activities.

- 9 axes machine: 7 linear axes provided with linear scales and 2 rotary axes equipped with direct angular encoders.

- Workpiece Direct Drive by torque-motors.

- Tool drive by Main spindle motors, with speed full range adjust thru electronic driver.

- Fixed centers in both chucks with no hydraulic sliding and chip build-up.

- Steady-rest NC controlled in an independent slide.

- Part settling control.

- Increased stiffness of the machine configuration.

- RFID of ID tools.

- Unobstructed chip shedding designed for dry machining.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so chips fall directly to the conveyor.

Machine architecture

Machining units

- 2 NC controlled workpiece units (W1, W2).

- 1 NC controlled independent steady rest (W3).

- 2 NC controlled tool spindle units (Z1/X1, Z2/X2), equipped with S1/S2 milling spindles.

- Reduced overhang distance from chuck face to front bearing and its guiding on the column.

Fixture

- 1 part per fixture.

- Rotary axes: synchronized C1 / C2.

- Part pre-locators, according to the geometry of Flange and Post-end:

a) Rotating pre-locators, fixed to the chuck.

b) Retractable pre-locators, for improved chip shedding.

Options

- D tool monitoring for single insert breakage detection.

- Vibration monitoring.

- Tool temperature monitoring.

- Spindles main bearings temperature monitoring.

- Torque-motors temperature monitoring.

-

1 Machining units

- 2 NC controlled workpiece units (W1, W2).

- 1 NC controlled independent steady rest (W3).

- 2 NC controlled tool spindle units (Z1/X1, Z2/X2), equipped with S1/S2 milling spindles.

- Reduced overhang distance from chuck face to front bearing and its guiding on the column.

-

2 Fixture

- 1 part per fixture.

- Rotary axes: synchronized C1 / C2.

- Part pre-locators, according to the geometry of Flange and Post-end:

a) Rotating pre-locators, fixed to the chuck.

b) Retractable pre-locators, for improved chip shedding.

-

3 Options

- D tool monitoring for single insert breakage detection.

- Vibration monitoring.

- Tool temperature monitoring.

- Spindles main bearings temperature monitoring.

- Torque-motors temperature monitoring.

We can help you with the manufacturing process of many other applications