tR

Introduction

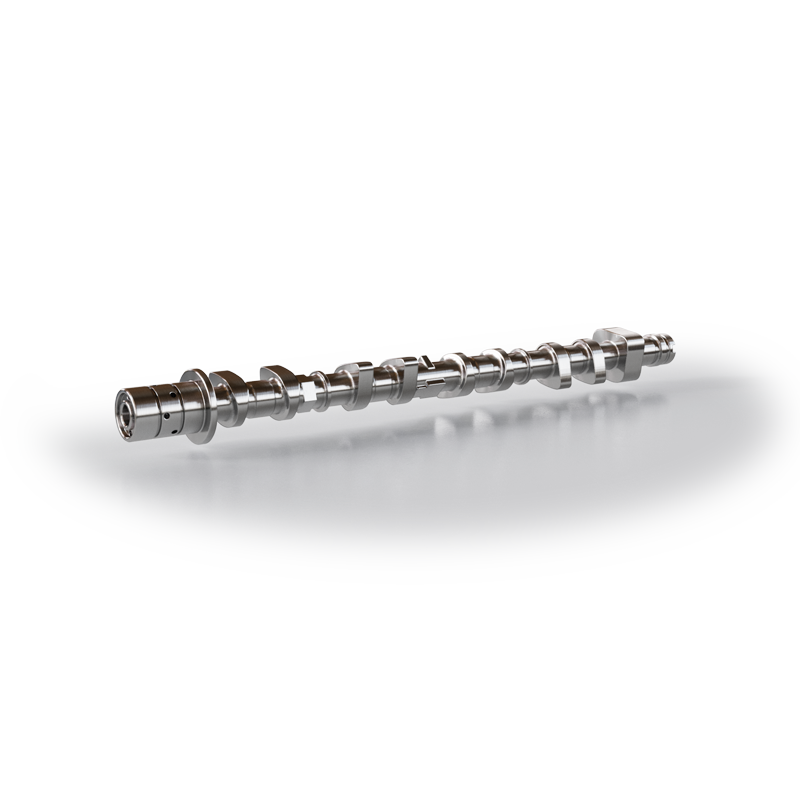

The tR series has been developed applying an extensive know-how of high productivity systems for steel and cast iron camshafts and crankshafts.

Based on a milling center configuration and our experience with the Xflex series, it is equipped with 2 sliding NC controlled workpiece driving spindles, a NC independent steady rest, and 2 TTB tool spindles offering extra capabilities and flexibility.

Thanks to its modularity, it is prepared to be retooled into an internal or an external milling machine.

Our unique configuration allows for an increased machine stiffness, improved chip shedding, and a safe and easy access for maintenance.

- High level of modularity between ID, OD and TTB.

- 2 sliding NC controlled workpiece drive spindles. Electronic spring to control force between centers.

- Standard off the shelf pull-down and compensating clamping chucks, with retractable jaws and fixed centers. Fully sealed and low maintenance.

- Highest stiffness of workpiece spindles, due to reduced overhang length from chuck face to guiding.

- Highest stiffness of tool spindles, due to bigger bearings.

- Automatic tool clamping.

- Low maintenance components, as the Direct Drive motors for workpiece spindles.

- Design focused on favoring chip shedding.

- Ergonomic design for tool change and maintenance activities.

- 9 axes machine: 7 linear axes provided with linear scales and 2 rotary axes for tool indexing.

- Workpiece Direct Drive by high speed torque-motors.

- Fixed centers in both chucks with no hydraulic sliding and chip build-up.

- Steady-rest NC controlled in an independent slide.

- Tool clamping with automatic high force draw-bar.

- Part and tool settling control.

- Tool precise indexing drive by servo-motor, and quick locking system for hard turning operations.

- Increased stiffness of the machine configuration.

- RFID of TTB tools.

- Higher stiffness of tool spindles, by a big ASA cone and increased face support.

- Unobstructed chip shedding designed for dry machining.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so chips fall directly to the conveyor.

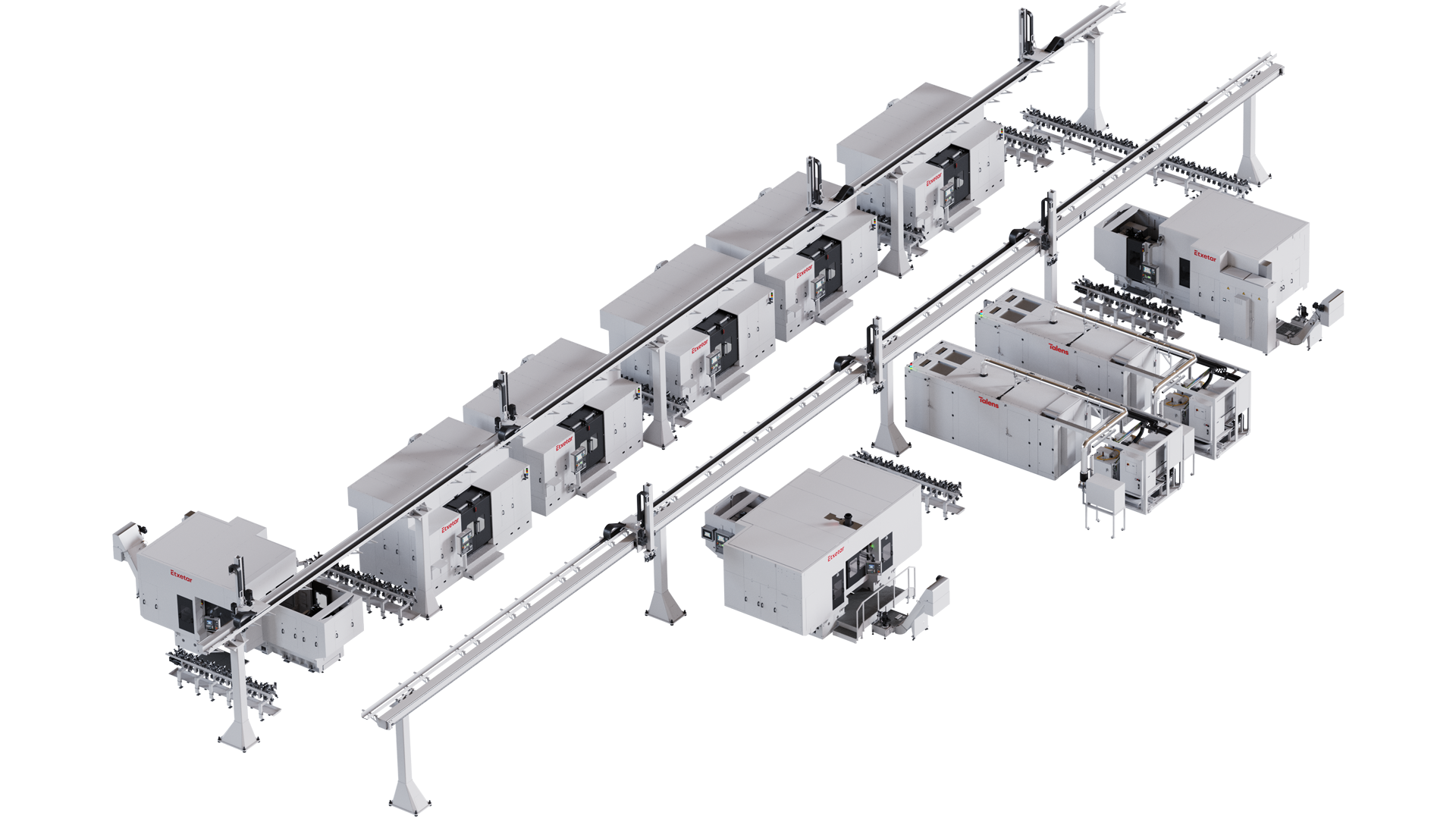

Machine architecture

Machining units

- 2 NC controlled workpiece units (W1, W2).

- 1 NC controlled independent steady rest (W3).

- 2 NC controlled tool units (Z1/X1, Z2/X2), equipped with Q1-Q2 turning / C3-C4 turn-broaching spindles.

- Reduced overhang distance from chuck face to front bearing and its guiding on the column.

Fixture

- 1 part per fixture.

- Rotary axes: synchronized C1 / C2.

- Part pre-locators, according to the geometry of Flange and Post-end:

a) Rotating pre-locators, fixed to the chuck.

b) Stationary pre-locators, fixed to workpiece spindle-housings.

c) Retractable pre-locators, for improved chip shedding.

Options

- TTB tool monitoring for single insert breakage detection.

- Vibration monitoring.

- Tool temperature monitoring.

- Spindles main bearings temperature monitoring.

- Torque-motors temperature monitoring.

-

1 Machining units

- 2 NC controlled workpiece units (W1, W2).

- 1 NC controlled independent steady rest (W3).

- 2 NC controlled tool units (Z1/X1, Z2/X2), equipped with Q1-Q2 turning / C3-C4 turn-broaching spindles.

- Reduced overhang distance from chuck face to front bearing and its guiding on the column.

-

2 Fixture

- 1 part per fixture.

- Rotary axes: synchronized C1 / C2.

- Part pre-locators, according to the geometry of Flange and Post-end:

a) Rotating pre-locators, fixed to the chuck.

b) Stationary pre-locators, fixed to workpiece spindle-housings.

c) Retractable pre-locators, for improved chip shedding.

-

3 Options

- TTB tool monitoring for single insert breakage detection.

- Vibration monitoring.

- Tool temperature monitoring.

- Spindles main bearings temperature monitoring.

- Torque-motors temperature monitoring.

We can help you with the manufacturing process of many other applications