HDC1500

Our twin spindle 5 axis CNC for parts up to 1500mm.

Introduction

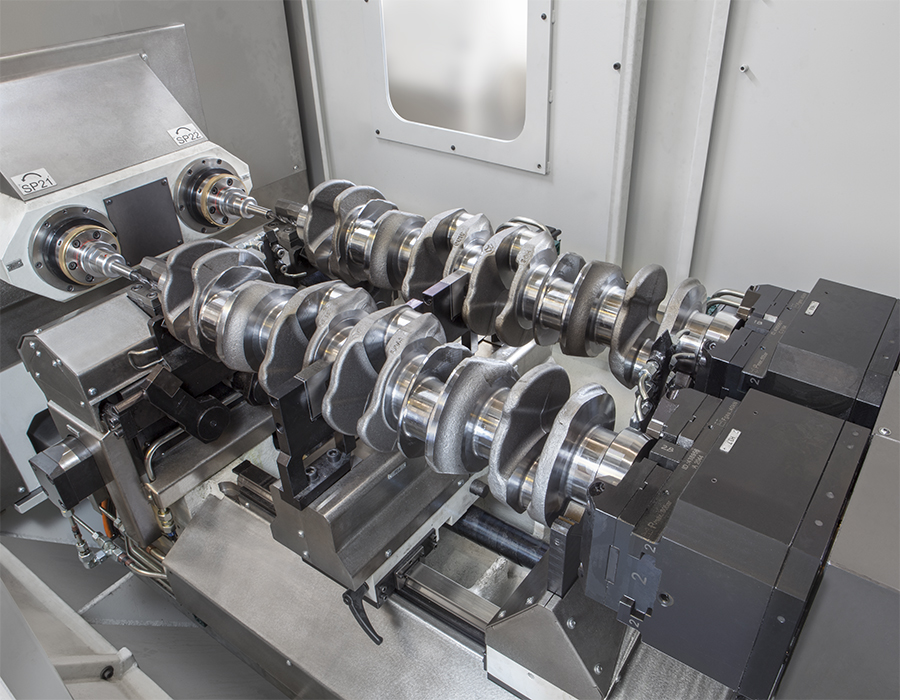

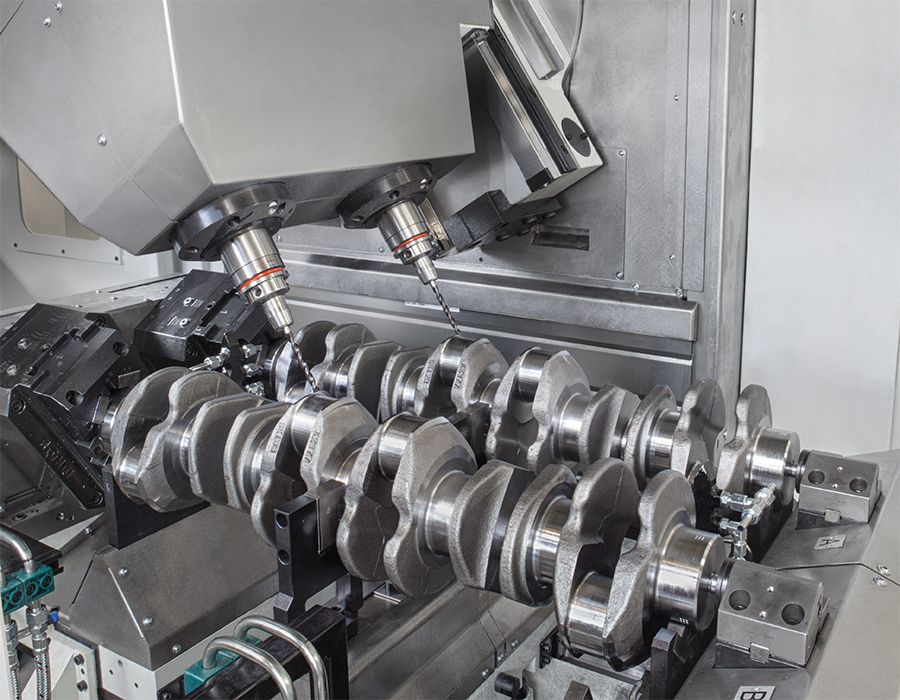

The HDC1500 is our twin spindle 5 axis machining center for rotating parts of up to 1500 mm. It’s especially suited to perform crankshaft oil hole drilling operations. Heavy duty.

- Compatible with Dry, MQL or high-pressure coolant machining.

- Design focused for optimal chip shedding.

- Ergonomic design for tool change and maintenance activities.

- Suitable configuration for robot or manual load.

- 4 or 5 axes machining center. All linear axes provided with linear scales.

- Tool interface HSK-63, HSK-80 or HSK-100. Other interfaces upon request.

- Conventional spindle.

- Chain type automatic tool changer.

- Multiple tool breakage detection systems (laser, mechanical check, tool monitoring, etc.).

- Tool presence control in the tool exchange position between spindle and magazine.

- Unobstructed chip shedding designed for MQL machining.

- Totally sealed stainless steel front guarding with no horizontal surfaces.

- Honeycomb bed design so chips fall directly to the conveyor.

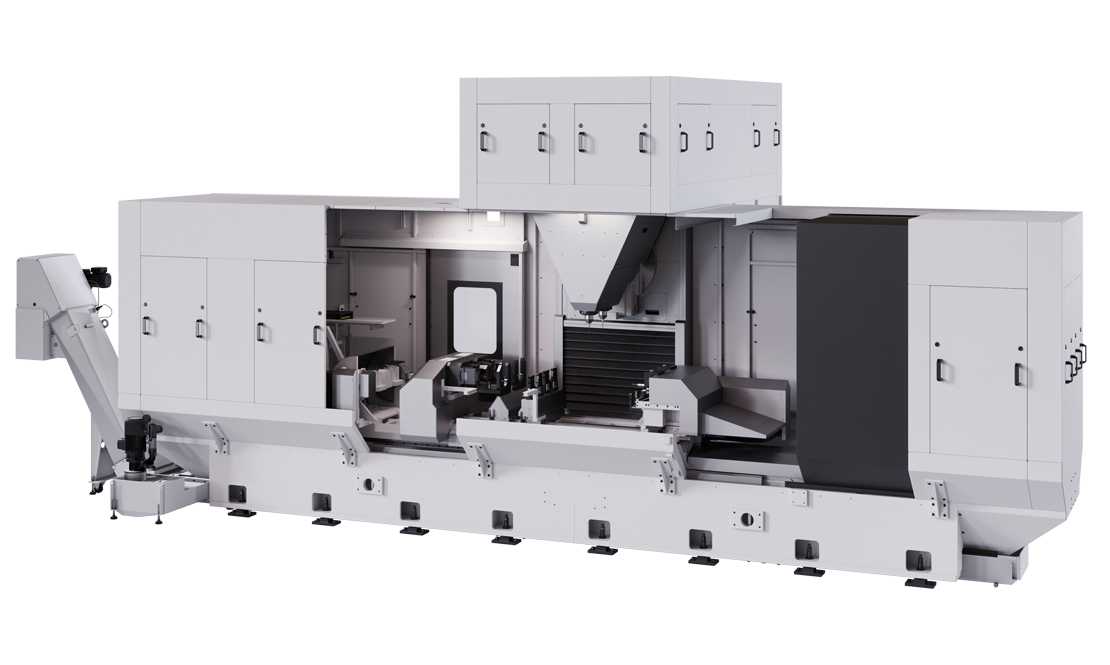

Machine architecture

Machining unit

- 3 axis unit (X/Y/Z).

- 1 or 2 spindles. Limited by the part swing diameter and machining process tolerances.

- 1 or 2 units, depending on the production volumes.

Fixture options

- 1 or 2 fixtures (one side only). Limited by the part swing diameter and machining process tolerances.

- Axes: A / B / A+B.

- NC motion in different fixture elements as an option.

Load/unload options

- Gantry load, by means of a loader integrated in the machine design.

- Robot load.

- Manual load. Directly to the fixture or by means of a loader integrated in the machine design.

1

2

3

-

1 Machining unit

- 3 axis unit (X/Y/Z).

- 1 or 2 spindles. Limited by the part swing diameter and machining process tolerances.

- 1 or 2 units, depending on the production volumes.

-

2 Fixture options

- 1 or 2 fixtures (one side only). Limited by the part swing diameter and machining process tolerances.

- Axes: A / B / A+B.

- NC motion in different fixture elements as an option.

-

3 Load/unload options

- Gantry load, by means of a loader integrated in the machine design.

- Robot load.

- Manual load. Directly to the fixture or by means of a loader integrated in the machine design.

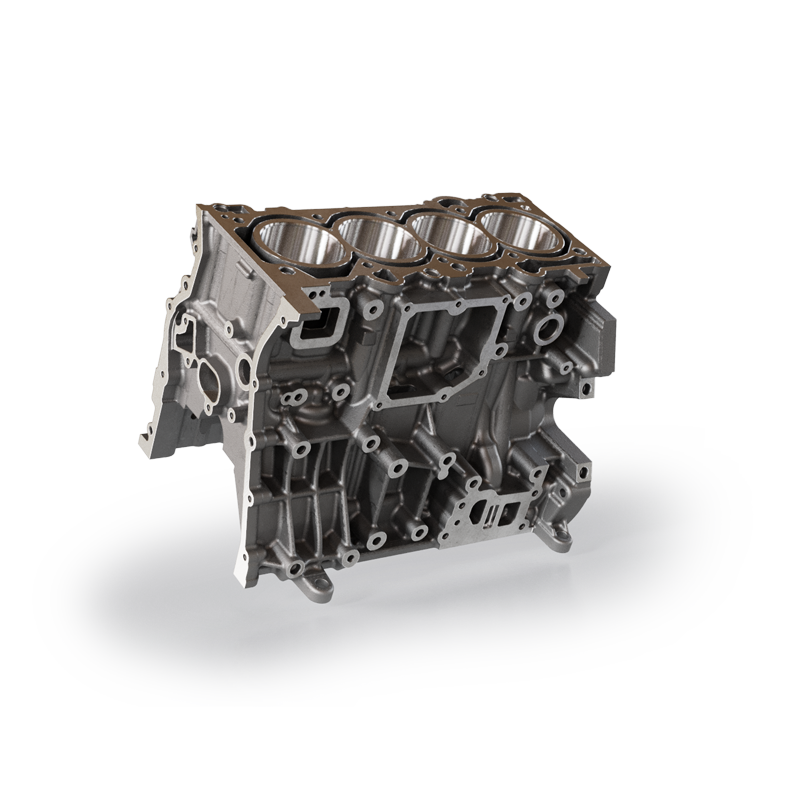

We can help you with the manufacturing process of many other applications