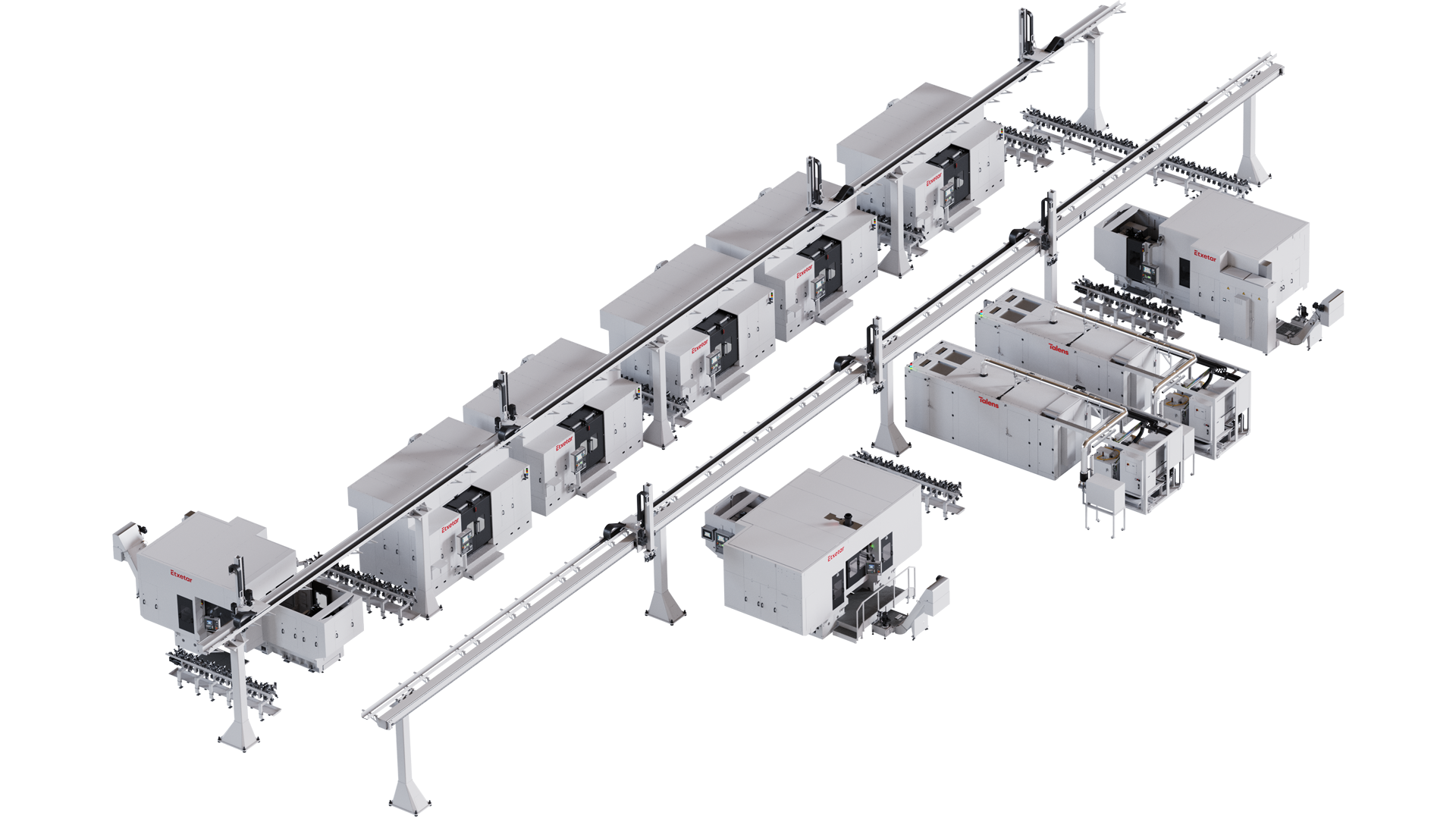

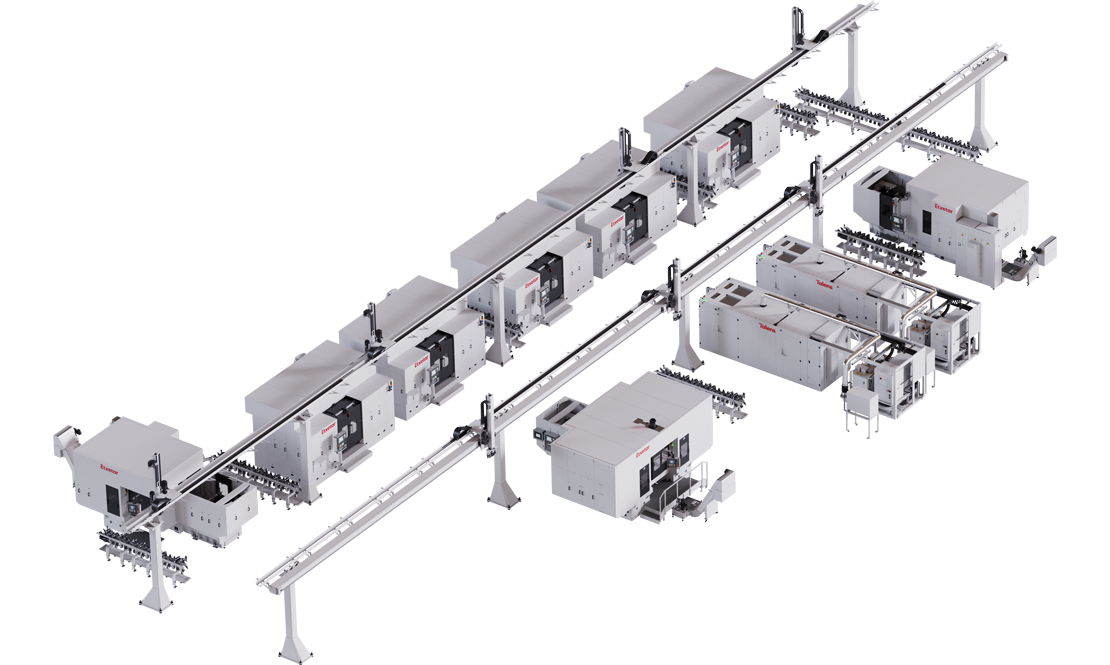

Crankshaft line

Introduction

Based on our experience in crankshaft manufacturing, Etxetar offers the supply of a complete crankshaft roughing line, from the process and tooling design to the final installation and acceptance at the customer plant.

- Machining process fixture and tooling design of the whole roughing line.

- Optimization of investment costs due to reduction of number of line suppliers, tryout parts and validation time.

- One single contact person for the entire roughing line.

- Management of sub suppliers.

- Centering and ends machining.

- Pin and main journal operations.

- Oil hole drilling.

- Pin and main lightening hole drilling.

- Pin and main hardening.

- Flange and post final hole machining.

Machine architecture

Mill to length and centering

Rough milling mains and pins

Rough milling mains and pins

TTB Turning concentrics

TTB Turning concentrics

Semi-finish milling

Oil hole drilling

Laser hardening

Laser hardening

Ends machining

-

1 Mill to length and centering

-

2 Rough milling mains and pins

-

3 Rough milling mains and pins

-

4 TTB Turning concentrics

-

5 TTB Turning concentrics

-

6 Semi-finish milling

-

7 Oil hole drilling

-

8 Laser hardening

-

9 Laser hardening

-

10 Ends machining

We can help you with the manufacturing process of many other applications